From Novice to Pro: Understanding Rebar Sizing

Rebar sizing is a fundamental aspect of construction that directly impacts the strength and durability of reinforced concrete structures. By selecting the appropriate rebar size and type, construction professionals can ensure the integrity and longevity of their projects. Whether it’s a residential building, a bridge, or a retaining wall, precise rebar sizing is crucial for safe and reliable structures in construction projects.

Why Understanding Rebar Sizing Is Crucial

Rebar sizes refer to the different diameters and configurations of steel reinforcement bars used to fortify concrete structures.

These bars are strategically placed within the concrete to enhance its tensile strength and overall structural integrity.

Understanding rebar sizes is crucial in construction as it directly influences the load-bearing capacity, durability, and safety of the final structure.

The Importance of Choosing the Right Rebar Size

Selecting the appropriate rebar size is essential to ensure that the reinforced concrete can withstand the applied forces and stresses over time.

The right rebar size distributes loads effectively, minimising the risk of cracking, bending, or structural failure.

Common Steel Rebar Sizing and Their Applications

6mm (D6) and 8mm (D8) Rebar

These smaller diameter rebars are commonly used in light construction projects, such as residential foundations, patios, and slabs.

10mm (D10) and 12mm (D12) Rebar

Medium-sized rebars find applications in various structures, including beams, columns, and medium-sized floor slabs.

16mm (D16) to 20mm (D20) Rebar

These larger diameter rebars are used in heavy-duty projects, such as bridges, high-rise buildings, and large industrial structures.

Stainless Steel Rebar Standards

Steel rebars come in various grades, with the most common ones being 40, 60, 75, 80, and 100. Each grade corresponds to a specific yield strength.

For instance, a grade 60 bar has a minimum yield strength of 60 KSI.

Understanding Tensile Strength

In the realm of rebar application, the consideration of tensile strength, also referred to as yield strength, takes centre stage.

This crucial metric serves as a comprehensive gauge of the steel’s overall robustness.

For heavy-duty applications, it is advisable to opt for high-yield steel with grade 500 reinforcement, boasting a tensile strength or yield strength of 500 N/mm2 (or Mpa).

Complying with the British Standard 4449:2005, which permits a maximum yield strength of 650 MPa (or N/mm2), ensures adherence to industry standards.

It is crucial to note here that merely increasing the diameter of the rebar alone will not result in doubled strength. The true determinant of strength lies in the quality of the steel grade employed.

What Do The Letters on Rebar Mean?

The identification process of reinforcing steel involves a sequence of markings.

Initially, a letter or symbol is used to indicate the producing mill.

Subsequently, the marking for the bar size follows.

The third symbol utilised in the marking system designates the type of reinforcing steel used, commonly denoted by “S” for carbon-steel (ASTM A615) or “W” for low-alloy steel (ASTM A706).

Factors Influencing Rebar Size Selection

Several factors influence the choice of rebar sizes for a specific construction project:

Structural Requirements

The loads and forces the structure will be subjected to play a significant role in determining the appropriate rebar size.

Environmental Conditions

In harsh environments, such as coastal areas or chemical-rich settings, construction professionals prefer utilising corrosion-resistant rebar sizes like stainless steel or GFRP.

Local Building Codes and Regulations

Ensuring compliance with local construction codes guarantees that the project meets safety standards and receives construction approval.

Different Types of Rebar

Stainless Steel Rebar: Properties and Applications

Stainless steel rebar earns renown for its exceptional corrosion resistance, positioning it as an ideal choice for structures exposed to harsh environments, such as coastal areas or industrial settings.

Its properties ensure that the reinforcement remains intact, even in the face of moisture and chemicals.

Epoxy Coated Rebar: Advantages and Best Uses

Epoxy coated rebar offers a protective layer that prevents direct contact between the steel and concrete.

This barrier reduces the risk of corrosion, making it suitable for projects where concrete’s tensile strength and long-term durability are crucial.

Carbon Steel Rebar: Versatility and Cost-effectiveness

Due to its versatility and cost-effectiveness, carbon steel rebar is a favoured choice with construction professionals.

It is suitable for a wide range of construction applications, including residential, commercial, and infrastructure projects.

Glass Fibre Reinforced Polymer (GFRP) Rebar: Lightweight and Corrosion-resistant

GFRP rebar (Glass Fiber Reinforced Polymer) is a lightweight alternative to traditional steel reinforcement.

Its non-metallic composition makes it corrosion-resistant, making it an excellent choice for projects in aggressive environments or where weight reduction is essential.

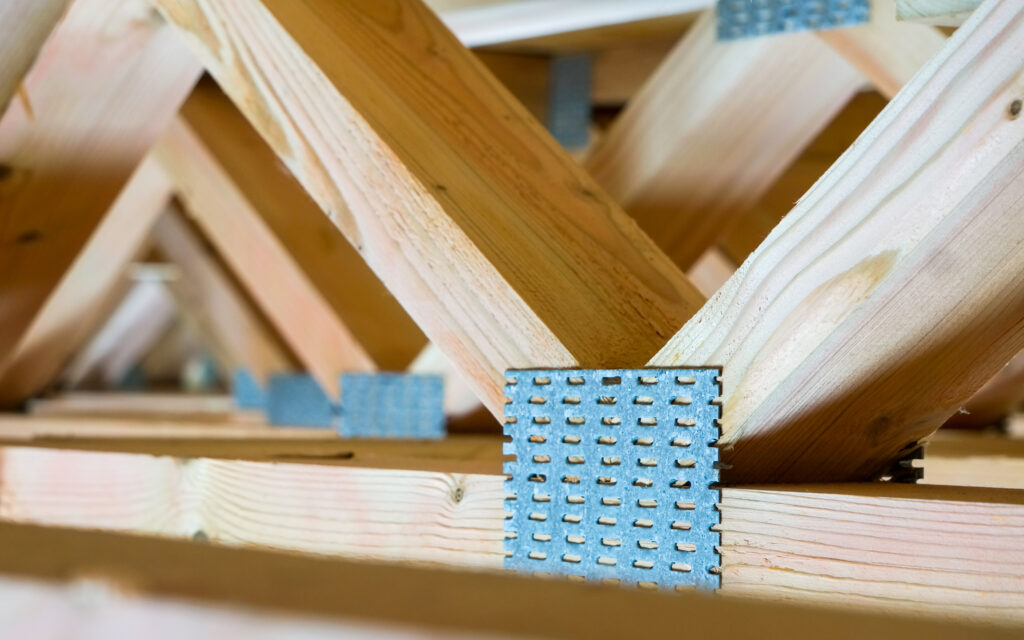

Welded Wire Fabric (WWF)

WWF rebar, despite having a distinct name from traditional rebar types, is essentially a grid pattern made from welding low-carbon steel wire.

This grid serves the purpose of reinforcing concrete slabs, thereby enhancing the concrete’s overall tensile strength.

Conclusion

As you can see, understanding rebar sizing is key to ensuring your concrete structure is as durable and long-lasting as possible.

While some of the core principles may be boring and technical, they’re essential steps in keeping your project alive for years to come.

Always ensure to do your research and work with experts when selecting which size of rebar you need for your project.