Installing A Lintel

| by Holly Wood

Installing a lintel is a vital step when constructing or renovating buildings. Lintels play a pivotal role in sustaining the structural integrity of a structure, especially around openings such as doors and windows.

In this comprehensive guide, we’ll explore the ins and outs of installing lintels correctly, ensuring a secure and long-lasting result.

What Are Lintels?

Lintels are horizontal elements generally made from either prestressed concrete or metal, designed to offer essential support for bearing loads across gaps between two vertical pillars.

These are frequently installed above doorways and large apertures in buildings, including load-bearing wall applications.

The Importance of Lintels

Lintels date back thousands of years, as evident in structures like Stonehenge in the UK. These horizontal supports span the openings in walls, diverting the weight from above, such as masonry or roof loads, to the walls on either side of the opening.

Imagine a window without a lintel: the entire weight of the masonry would rest on the window frame, which could lead to structural failures. By redistributing this weight, lintels prevent undue pressure on window and door frames.

Getting Started: How To Install a Lintel

Understand the Minimum End Bearing

Every lintel, whether steel lintel or concrete lintel, demands a proper minimum end bearing.

This bearing is the part of the lintel that sits on the masonry, supporting the wall’s weight. Ideally, it should extend a minimum of 150mm on both sides of the opening. Although some cases might permit a lesser extension, consulting with a manufacturer or supplier is crucial.

Bedding the Lintel on Mortar

Laying the lintel on a bed of mortar ensures even distribution of loads. This bed aids in managing potential irregularities between the lintel and its supporting masonry. When working with cavity wall applications, it’s pivotal to bed the lintel on both the inner and outer leaves, providing balanced weight distribution.

Ensuring the Lintel is Level

A spirit level becomes your best friend here. Check for levelness across the length and width of the lintel. Any imbalance could result in unequal pressure on the masonry, causing potential structural issues.

Let the Mortar Cure

Before placing any point loads or heavy components on the lintel, ensure the mortar has cured completely. If you’re short on time, ensure you use temporary propping beneath the lintel to prevent any shock loading.

Symmetrical Bricklaying

While laying bricks above the lintel, balance the load by laying bricks on both the inner and outer leaves simultaneously. Such a method ensures that the pressures on each side remain balanced, reducing risks of damage.

Damp Proof Course (DPC) Installation

Per the guidelines of BS EN 1996-2:2006 and NHBC standards, it’s mandatory for all external wall lintels to have a flexible damp proof course installed, unless they are sufficiently shielded by features like an eaves overhang or an equivalent protective measure.

In cavity walls, incorporating a damp proof course is crucial. The DPC, often made of a flexible damp proof material, prevents moisture from transferring between the inner and outer leaves of the wall. For masonry buildings, a minimal fall of 150mm for the DPC is a general guideline.

When to Use Propping

Depending on the lintel type, some might require temporary propping until the mortar sets. For lintels with a channel design, propping becomes crucial as the masonry built into the channel provides additional strength. Always refer to the manufacturer’s recommendations.

Best Practices and Key Takeaways

- Always adhere to manufacturer guidelines during installation.

- When uncertain about the lintel’s structural performance, seek advice from the manufacturer’s technical department.

- Steel lintels typically require propping at intervals of 1.2m and should remain in place until the mortar cures.

- Use full bricks or blocks as bearing areas. Avoid bearing onto cut blocks.

- Ensure a flexible damp proof course extends at least 50mm beyond the cavity return in cavity walls.

- Balance the construction of inner and outer leaves to avoid excessive eccentricity.

- Avoid letting masonry overhang any lintel flange by more than 25mm.

- Allow masonry to cure fully before applying any floor or roof loads.

- When installing concrete floor units or similar weighty elements over a lintel, it’s essential to handle with caution to prevent shock loading, and such units should be carefully positioned without dragging.

- To improve the visual appeal of an exposed underside of a lintel, one can utilise lintel soffit cladding.

Conclusion

Installing a lintel might seem daunting, but with the right knowledge and approach, it’s a straightforward process.

Whether you’re using steel lintels, concrete lintels, or even traditional stone lintels, following these guidelines will ensure a safe and secure installation.

Remember, when in doubt, always consult experts or the manufacturer’s technical department. Your structure’s safety and longevity depend on it!

Related Posts

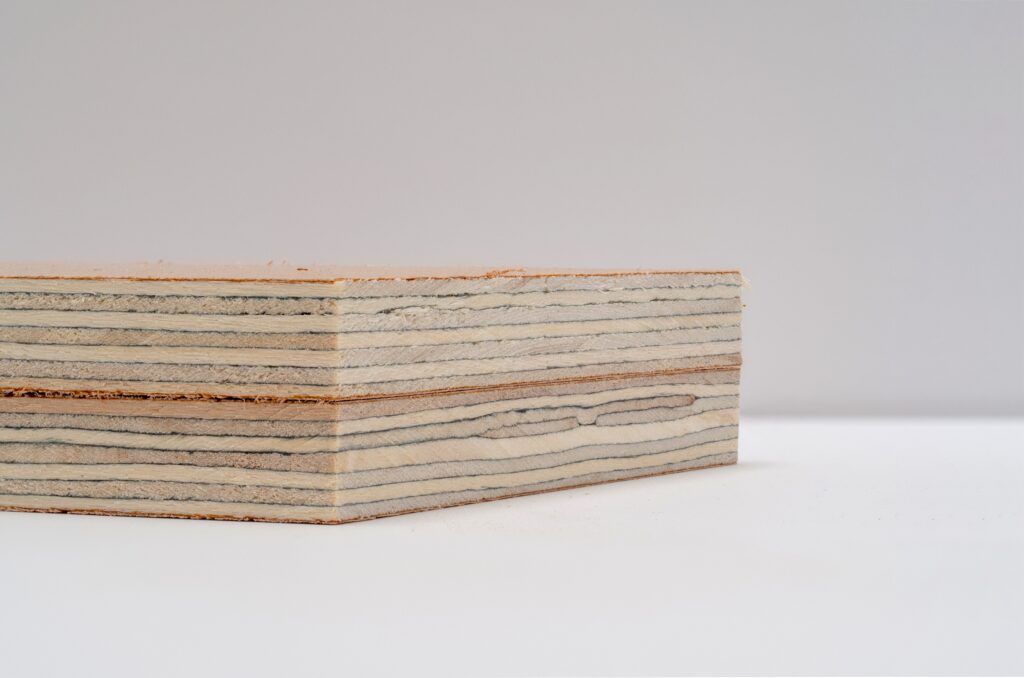

Chipboard vs MDF: Unveiling the Differences and Making the Right Choice

40 Financial Experts Reveal If Investing In Real Estate Is Worth It

International Men’s Health Week: Our study into men’s health and a medical guide to treating common ailments

Insulation Rolls vs Insulation Slabs: Which Type is Better in a Partition Wall

Battle of the Builder’s Brew! Best way to make tea revealed (it’s never milk first, FYI)

Tidy house, tidy mind: Over half of Brits start DIY and home improvement projects to help mental health

Best in the bedroom: Survey reveals tradesmen make the best lovers

32% increase in ‘Doomsday Preppers’ building bunkers and safehouses