How Is MDF Made?

| by Holly Wood

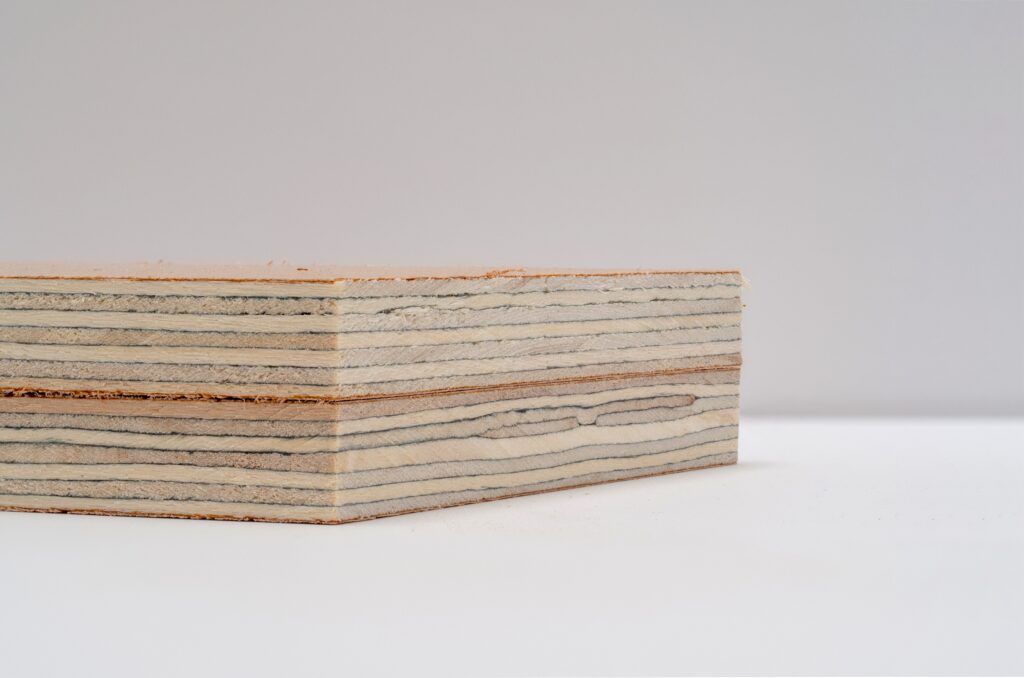

Unraveling the Mystery: How is MDF Made?

Ever pondered over the process of making MDF boards? Whether you’re a layman guessing it’s just ‘wood and glue’, or an industry expert familiar with every tiny detail, this article serves to enlighten everyone.

In this comprehensive guide, we’ll peel back the layers of the production process, revealing the alchemy that turns humble wood chips into one of the construction industry’s most revered materials.

MDF: Unpacking the Basics

MDF, standing for Medium Density Fibreboard, is a type of engineered wood product. It has carved out its place in the realms of furniture making, interior decoration, and beyond.

Unveiling the MDF Creation Process: A Step-By-Step Walkthrough

Step 1: Collection and Preparation of Raw Material

Every great story has a beginning. For MDF, it’s the collection of wood residuals. These byproducts, sourced mainly from forestry operations and lumber mills, undergo chipping into small pieces. Afterward, a drying phase eliminates the extra moisture, priming them for the stages that follow.

Step 2: Emergence of Wood Fibres

Next, a defibrator enters the scene. It subjects the chipped wood to heat and pressure, leading to the emergence of individual fibres. This step results in a pulp-like substance that forms the main component in MDF production.

Step 3: Application of Resin

As the journey continues, bonding agents get their turn. The most common choice is urea-formaldehyde resin, but alternatives like phenol-formaldehyde occasionally make an appearance for moisture-resistant MDF. Additionally, certain additives contribute to enhancing fire and pest resistance.

Step 4: The Pressing of the Fibre-Resin Mixture

Following the resin application, the fibre-resin mix gets fed into a hot press. Here, heat and pressure forge the fibres into a unified, solid sheet. The flexibility at this stage allows for a variety of product thicknesses.

Step 5: Final Touches to the Product

Post-pressing, the MDF sheet cools down and undergoes a sanding process. This step guarantees a smooth surface. Depending on its destined use, the MDF might receive a seal, veneer, or laminate as a finishing touch.

Conclusion

In answering the question “how is MDF made”, we’ve traversed a fascinating journey. It starts with unassuming raw wood residuals and culminates in a finished, versatile product. This process is nothing short of an engineering marvel.

By gaining this deeper insight, we’re able to appreciate MDF’s significant contributions across numerous sectors. We hope you found this peek into the MDF production process enlightening.

Related Posts

Chipboard vs MDF: Unveiling the Differences and Making the Right Choice

40 Financial Experts Reveal If Investing In Real Estate Is Worth It

International Men’s Health Week: Our study into men’s health and a medical guide to treating common ailments

Insulation Rolls vs Insulation Slabs: Which Type is Better in a Partition Wall

Battle of the Builder’s Brew! Best way to make tea revealed (it’s never milk first, FYI)

Tidy house, tidy mind: Over half of Brits start DIY and home improvement projects to help mental health

Best in the bedroom: Survey reveals tradesmen make the best lovers

32% increase in ‘Doomsday Preppers’ building bunkers and safehouses