Drying Screed: A Comprehensive Guide

When it comes to floor construction, one of the key components that often raises questions is screed. Whether you’re working on a residential project or a large-scale commercial venture, understanding the drying process of floor screed and when to begin laying flooring is crucial. In this comprehensive guide, we’ll address the often-asked question “How long does screed take to dry?” by delving into the various types of screeds, factors affecting drying times, and tips to expedite the process when necessary.

Understanding Floor Screed

Before we dive into the drying process, let’s establish what floor screed is.

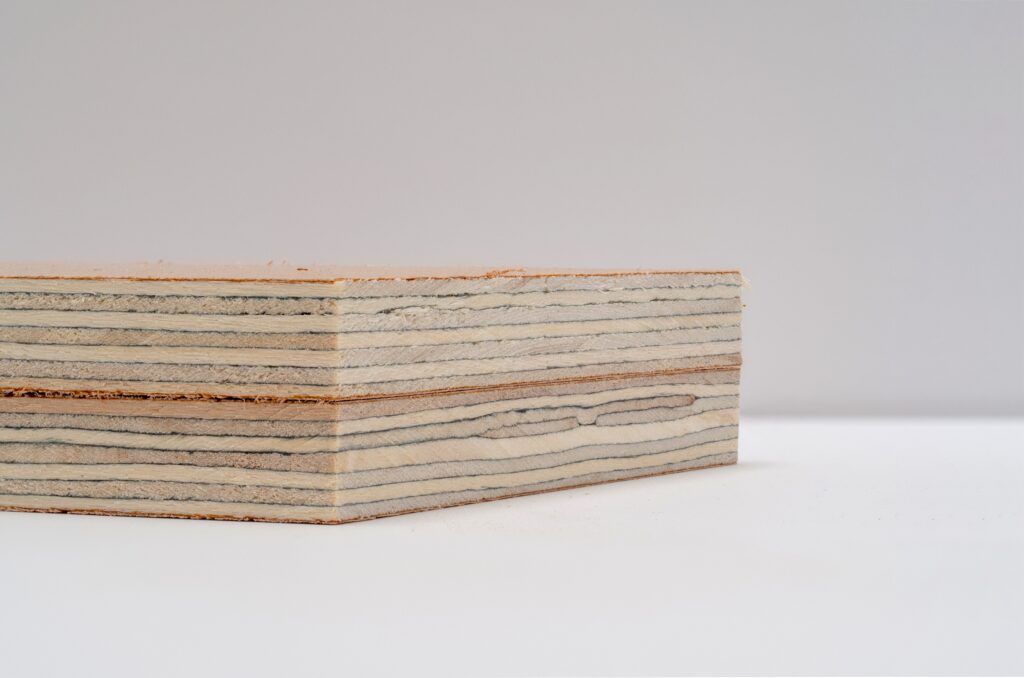

Floor screeds are a layer of material, typically a mixture of sand, cement, and water, that is applied over a concrete subfloor or as part of an underfloor heating system.

Its primary purpose is to create a smooth, level surface on which the final floor covering, such as tiles, carpet, or hardwood, can be laid.

Tips to Expedite the Drying Process

In some cases, you may need to accelerate the drying of the screed to meet tight project deadlines. Here are some methods to consider:

Force Dry

Using industrial heaters or fans can help speed up the drying process. However, caution must be exercised to avoid drying too quickly, which may lead to cracks.

Open Windows

Improving ventilation by opening windows can help reduce moisture levels and enhance drying, especially in well-ventilated areas.

Heat

Increasing the temperature of the construction site can expedite the drying process. However, it’s essential to monitor and control the temperature to prevent any adverse effects.

Screed Drying Times

There are several types of screed flooring available, each with its own unique characteristics and drying times:

Traditional Screed

Composition: Traditional screed is a blend of sand and cement, typically mixed at a ratio of 1 part cement to 3-5 parts sand, with 1:4 being a common ratio.

Setting Time: Traditional screed generally sets within 24-48 hours after application.

Drying Time: It typically dries at a rate of approximately 1mm per day.

Granolithic Screed

Composition: Granolithic screed is renowned for its enduring and tough attributes, attributed to the inclusion of notably tougher aggregates than those found in liquid screed. This renders it the preferred selection for areas subjected to intensive use, particularly in settings such as industrial flooring applications where durability is of utmost importance.

Setting Period: Typically, granolithic screed solidifies within a span of 12-28 hours after the initial application.

Drying Duration: Its drying pace averages around 2mm per day, rendering it apt for demanding environments where strength and resilience are crucial.

Flowing Screed (Liquid Screed)

Composition: Flowing screeds, commonly referred to as liquid screeds, feature a reduced quantity of finer aggregates compared to traditional screeds. This composition improves ease of handling and results in a more polished surface, rendering it well-suited for specific applications.

Setting Time: Flowing screed generally sets within 6-48 hours, offering a reasonable timeframe for project progression.

Drying Time: It typically dries at a rate of around 1mm per day, making it suitable for a variety of internal projects and underfloor heating installations.

Fast-Drying Screed

Composition: Engineered for quick setting and drying, fast-drying screed expedites project timelines.

Setting Time: Fast-drying screed boasts a rapid setting time, typically within 1-2 hours after application.

Drying Time: Its drying rate is impressively swift, at around 10-15mm per day, significantly faster than traditional screed.

Drying Time Variables

Several factors can influence how long screed takes to dry. Understanding these variables is crucial for successful project planning:

Ambient Temperature

The temperature of the surrounding environment plays a significant role in the drying process. Higher temperatures typically result in quicker drying periods.

Moisture Levels

The initial moisture content of the screed material can affect drying times. Most screeds need to dry until they are completely dry to ensure a stable surface for flooring installation.

Thickness

The thickness of the screed layer can vary depending on the project’s requirements. Thicker screeds will typically take longer to dry than thinner ones.

Humidity

Humidity levels in the construction site can impact drying. High humidity may slow down the drying process, while low humidity can expedite it.

Underfloor Heating

When underfloor heating pipes are installed, it’s essential to follow specific guidelines to ensure proper drying. Heat should be gradually introduced to prevent cracking.

Conclusion

In conclusion, understanding how long screed takes to dry is essential for the successful completion of any construction project.

Factors such as the type of screed, site conditions, and project requirements can all affect drying times.

By considering these variables and employing appropriate techniques when necessary, you can ensure that your screed floor is ready for the installation of the final floor covering within the desired timeframe.

Always consult with professionals to make informed decisions and achieve the best results for your specific project.