How To Cut Insulation Rolls

Knowing how to cut insulation rolls might seem like a straightforward task, but it requires the right tools, techniques, and precautions to ensure you achieve clean and accurate cuts.

In this comprehensive guide, we’ll walk you through the steps to cut insulation rolls effectively and safely.

The Importance of Clean Cuts When Installing Insulation

Achieving clean cuts when cutting insulation rolls is paramount for a successful insulation installation.

Here’s why:

- The precision of your cuts directly impacts the effectiveness of your insulation, ensuring a snug fit and optimal coverage.

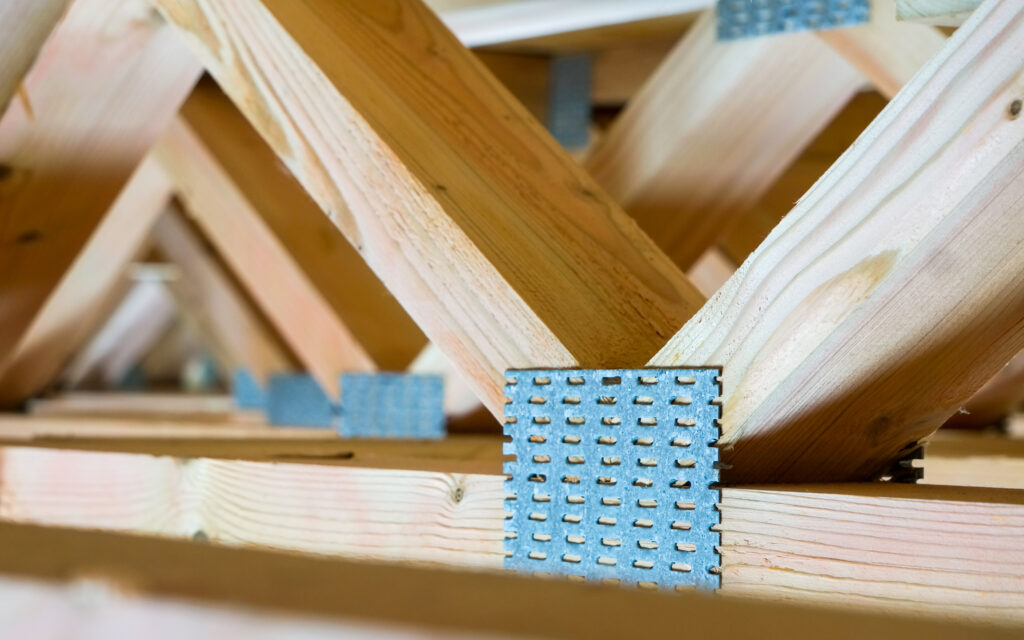

- Clean cuts enable the insulation material to fit seamlessly between joists, rafters, or other structural elements, reducing the risk of gaps or uneven coverage.

- Properly cut insulation also minimises the potential for heat loss or gain, as well as drafts, which are common concerns addressed by installing insulation.

- Additionally, accurate cuts prevent unnecessary material wastage, saving both time and resources during the installation process.

Gather the Necessary Tools and Safety Gear

Before you begin cutting insulation rolls, it’s essential to have the right tools and safety equipment in place. Here’s what you’ll need:

- Utility knife or insulation knife

- Sharp pair of scissors or shears

- Permanent marker

- Tape measure

- Safety glasses or goggles

- Protective clothing, including long pants, long-sleeved shirt, and gloves

- Protective dust mask or respiratory mask

- Safety gloves

- Safety gear, including safety goggles and gloves

Prepare the Insulation Roll

- Measure and Mark: Lay the insulation roll flat on a clean, flat surface. Use a measuring tape to determine the required length of insulation. Mark the cut line accurately using a permanent marker.

- Secure the Roll: To prevent the insulation roll from shifting during the cutting process, you can secure it in place using heavy objects or clamps.

Cutting Techniques for Different Types of Insulation

The most straightforward approach to cutting your insulation rolls varies, in part, based on the material that makes up your blanket insulation – be it mineral wool, fibreglass, or sheep’s wool.

Fiberglass Insulation Rolls

- Sharp Utility Knife: For fiberglass insulation rolls, a sharp utility knife is your best tool. Position the knife along the marked line and cut through the insulation in a single stroke. Use consistent pressure to achieve a clean cut.

- Scissors or Shears: Alternatively, you can use a pair of sharp scissors or shears to cut fiberglass insulation. Open the scissors wide and make a straight cut along the marked line.

Loft Insulation Rolls

- Use an Insulation Knife: Loft roll often requires a longer blade to cut through the thicker material. An insulation knife with a long blade and sharp edge can provide the necessary reach for accurate cuts.

- Carving Knife: In some cases, a carving knife can also be effective for cutting loft insulation rolls. Its long, serrated blade can handle the dense material with ease.

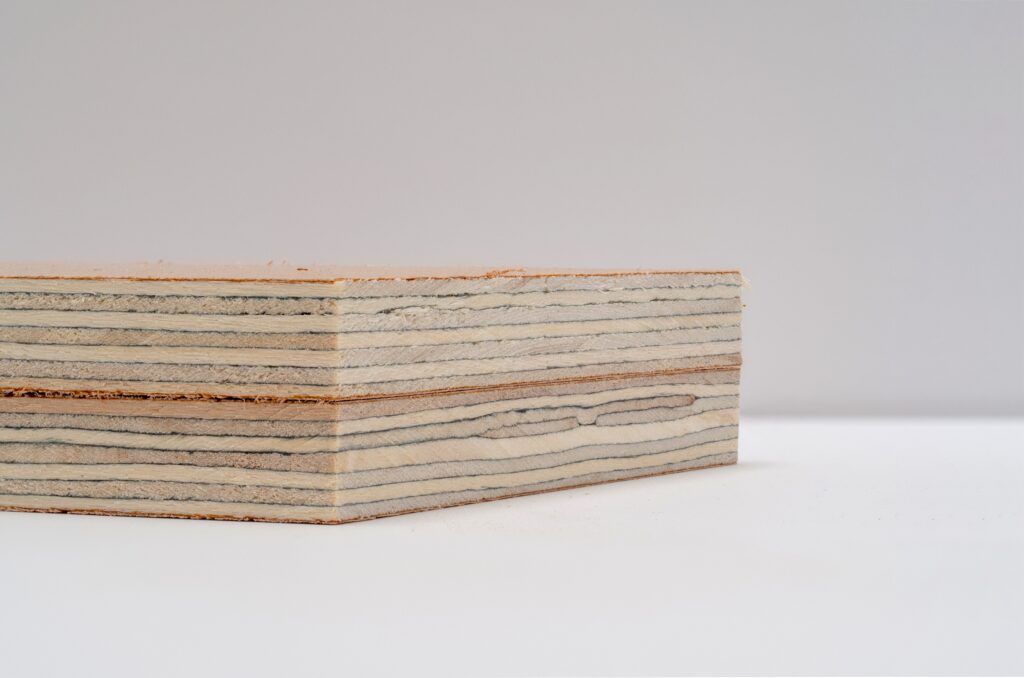

Fibreglass Insulation Batts

- Bread Knife: To cut fiberglass insulation batts, a bread knife with a serrated edge can work well. Its saw-like motion can help you achieve a straight cut without compressing the material too much.

- Sharp Knife: A sharp knife with a short blade can also be used to cut fibreglass insulation batts. Make sure the blade is sharp to avoid tearing the insulation.

Mineral Wool Insulation

- Utility Knife: Mineral wool insulation can be dense and resistant, so a sharp utility knife is recommended. Hold the knife steady and cut along the marked line with steady pressure.

- Long-Bladed Scissors: Long-bladed scissors can be an alternative for cutting mineral wool insulation. Make sure the scissors are sharp and cut steadily to avoid compressing the material.

Safety Precautions

- Wear Safety Gear: Always wear safety goggles, gloves, and a protective dust mask to prevent skin irritation and inhaling dust particles.

- Work in a Well-Ventilated Area: If possible, work in a well-ventilated area to avoid inhaling dust and fumes.

- Work Carefully: Take your time and work carefully to ensure accurate and clean cuts.

- Avoid Inhaling Dust: When cutting insulation, especially fiberglass, take measures to avoid inhaling dust. A protective dust mask or respiratory mask is crucial.

Tips for Accurate Cuts

- Follow Marked Lines: Always cut along the marked line to ensure your insulation pieces are accurately measured.

- Use Straight Cuts: Maintain a straight cutting motion to achieve clean edges.

- Check for Tight Spots: If you’re cutting insulation for tight spots, measure and mark accurately to prevent over-cutting.

- Measure Multiple Times: Measure multiple times before cutting to avoid mistakes and wasted material.

- Consider Joist Spacings: When cutting insulation for installation between joists, consider the spacing between them. Cut the insulation slightly wider to ensure a snug fit.

- Cut Extra Length: It’s better to cut insulation slightly longer than needed. You can always trim off any excess, but you can’t add material back once it’s cut too short.

Conclusion

Cutting insulation rolls accurately and safely requires the right tools, techniques, and safety precautions.

Whether you’re working with fiberglass insulation, loft insulation rolls, or other materials like fibreglass insulation batts or mineral wool, following these guidelines will help you achieve clean and precise cuts.

Remember to prioritise safety by wearing protective clothing, safety glasses, gloves, and a dust mask. With careful attention to detail, you can ensure that your insulation installation is effective and energy-efficient.