How to Install XPS Insulation

| by Holly Wood

When it comes to making your building more energy-efficient, reducing utility bills, and creating a comfortable living or working space, knowing how to install XPS insulation is an invaluable skill.

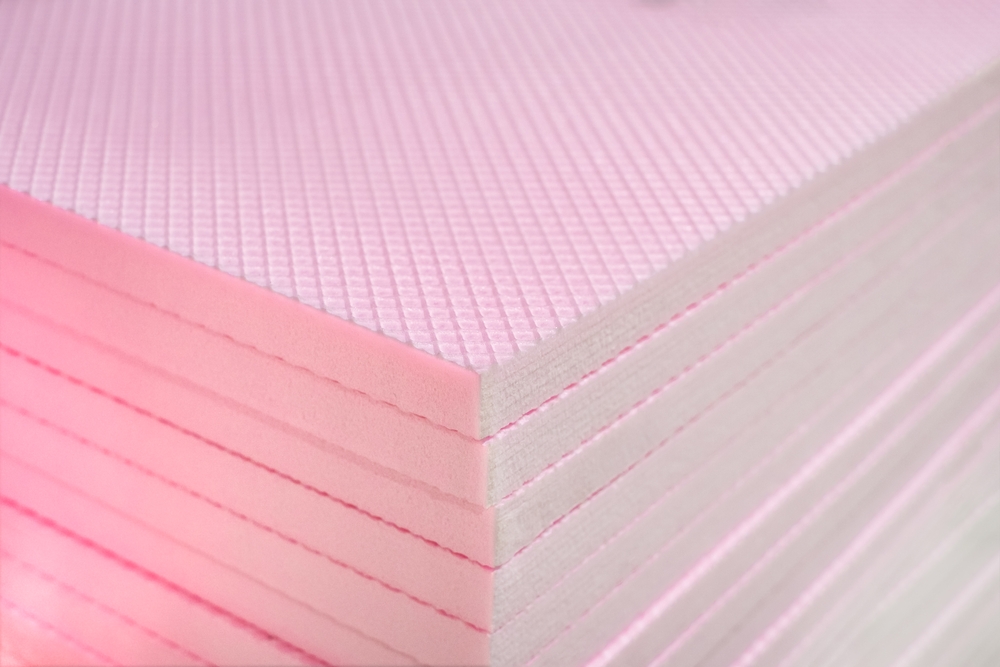

XPS insulation, short for extruded polystyrene insulation, is renowned for its high thermal resistance and many benefits in construction. In this comprehensive guide, we will take you through the step-by-step process of installing XPS insulation.

From understanding its properties and selecting the right tools to the actual installation, we’ll provide you with all the information you need to ensure a successful and energy-efficient project.

Understanding XPS Insulation

XPS insulation boards, also referred to as XPS foam insulation, are a type of continuous insulation board known for their exceptional thermal resistance.

These insulation boards are manufactured through a precise extrusion process, resulting in a closed-cell structure that imparts them with high compressive strength. This structural integrity makes XPS insulation boards an ideal choice for various building applications.

Beyond their compressive strength and high thermal resistance, XPS foam insulation offers several benefits, including durability and moisture resistance, making them a trusted option for both residential and commercial construction projects.

Tools and Materials

Before you start installing XPS insulation, gather the following tools and materials:

- XPS insulation boards

- Utility knife

- Adhesive

- Measuring tape

- Paint (optional)

- Safety gear (gloves, goggles, and a dust mask)

Steps to Install XPS Insulation

1. Prepare the Surface

Before installing the insulation, make sure the surface is clean and free from any debris or dust. If the surface is rough or uneven, consider using a paint or adhesive to create a smooth and compatible surface for the XPS boards.

2. Measure and Cut

Next, measure the area where you intend to install the XPS insulation boards. Use a measuring tape to ensure accurate dimensions. Once measured, use a utility knife to cut the XPS boards to the appropriate size.

3. Cut Openings

If your project involves XPS insulation installation around windows, doors, or other openings, carefully cut and fit the insulation boards to create a snug and effective seal.

4. Apply Adhesive

Apply adhesive to the back of the XPS insulation boards. Ensure even coverage to create a strong bond between the boards and the surface.

Follow the manufacturer’s recommendations for the type of adhesive to use.

5. How To Install XPS Insulation

Press the XPS insulation boards firmly onto the prepared surface, ensuring that they are properly aligned and tightly fitted together. Pay close attention to the seams to prevent any gaps that could affect the insulation’s thermal performance.

6. Finish the Project

Once all the XPS insulation boards are in place, you can proceed with the construction or renovation project as intended.

Be sure to cover the insulation with the appropriate finishing materials, such as plasterboard or siding, to protect it from damage.

Testing and Quality Assurance

After the installation is complete, consider testing the insulation’s effectiveness to ensure it meets your desired energy efficiency goals.

Manufacturers often provide guidelines for testing XPS insulation to verify its performance.

Conclusion

In conclusion, installing XPS insulation can be a cost-effective way to enhance your building’s energy efficiency, save money on energy bills, and create a more comfortable living or working environment.

By following the steps outlined in this guide and using the right tools and materials, you can achieve the best results with XPS insulation and enjoy its many benefits.

Related Posts

Chipboard vs MDF: Unveiling the Differences and Making the Right Choice

40 Financial Experts Reveal If Investing In Real Estate Is Worth It

International Men’s Health Week: Our study into men’s health and a medical guide to treating common ailments

Insulation Rolls vs Insulation Slabs: Which Type is Better in a Partition Wall

Battle of the Builder’s Brew! Best way to make tea revealed (it’s never milk first, FYI)

Tidy house, tidy mind: Over half of Brits start DIY and home improvement projects to help mental health

Best in the bedroom: Survey reveals tradesmen make the best lovers

32% increase in ‘Doomsday Preppers’ building bunkers and safehouses