Chipboard vs MDF: Unveiling the Differences and Making the Right Choice

The time-old debate of “Chipboard vs MDF” has long been a subject of contention among woodworking enthusiasts and professionals alike.

In the realm of construction, where every choice matters, the decision between chipboard and MDF (medium-density fibreboard) carries significant weight.

These two popular engineered wood materials stand as formidable contenders, each with its own set of unique characteristics and applications.

Embark with us on an informative journey as we unveil the differences, intricacies, and nuances of chipboard vs MDF, guiding you through the decision-making process.

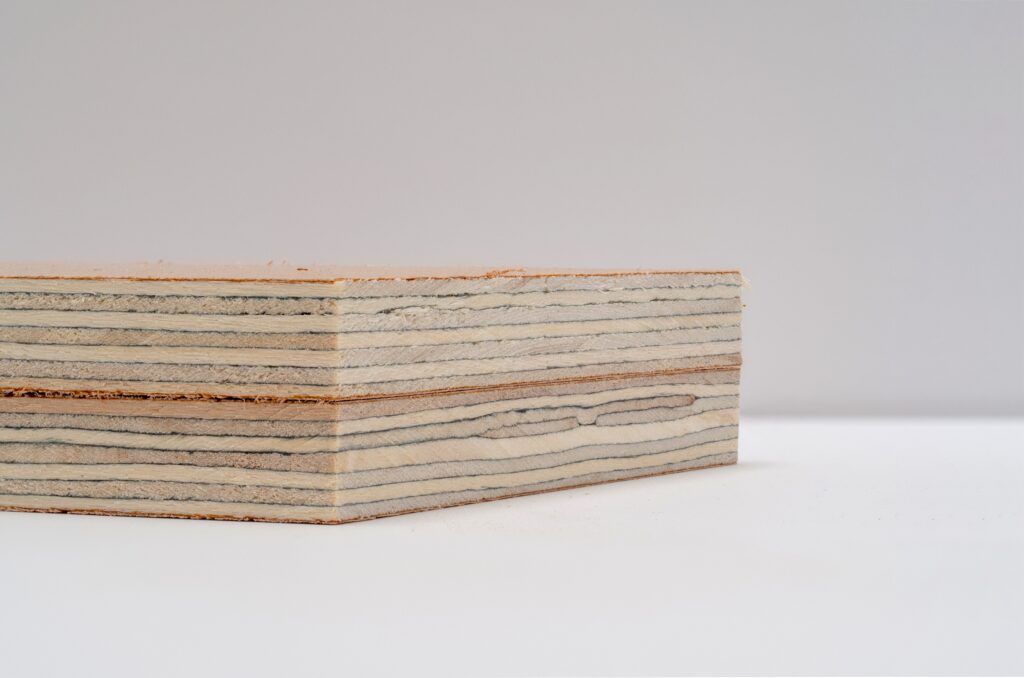

What is Chipboard?

Chipboard, also known as particleboard, is a versatile engineered wood product. It is made by compressing wood particles, such as chips, sawdust, and resin, under high pressure and heat. The result is a flat panel with a smooth surface, available in various thicknesses and grades.

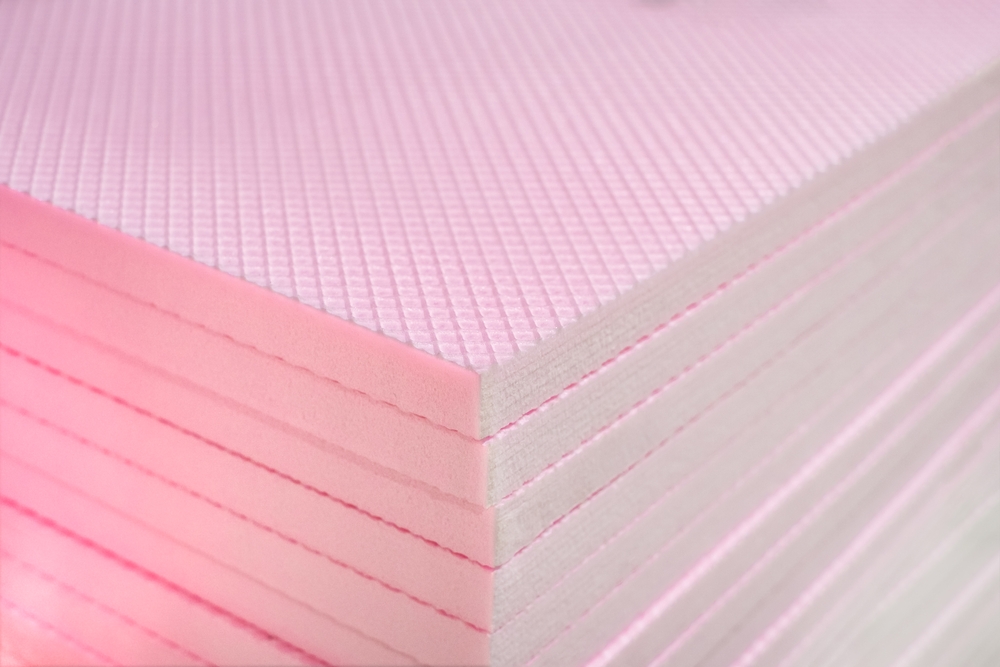

What is MDF?

MDF, or medium-density fiberboard, is another popular option in the realm of engineered wood products. It is manufactured by breaking down wood fibers into fine particles and combining them with a resin binder, followed by high-pressure compression. The resulting panel has a dense and uniform composition, offering a smooth and consistent surface.

Material Composition and Structure: Chipboard vs MDF

Both chipboard and MDF are composite materials made from wood fibres or particles. However, their manufacturing processes and structural compositions differ.

Chipboard is typically coarser in texture, with visible wood particles, while MDF has a finer and more uniform texture due to the smaller fibre size. This distinction affects their characteristics and performance.

Durability and Strength: Comparing Chipboard and MDF

When it comes to durability and strength, MDF has an edge over chipboard. The uniform composition of MDF lends it greater stability, density, and resistance to warping or splitting.

Chipboard, although less robust, still offers sufficient strength for many applications.

Considering the load-bearing requirements and intended application of the material will provide valuable guidance in determining the appropriate choice between chipboard and MDF.

Moisture Resistance: Evaluating Chipboard and MDF Performance

One crucial factor to consider is the moisture resistance of chipboard and MDF.

Chipboard is more susceptible to moisture damage, as the wood particles within it can absorb water and cause swelling or deterioration.

On the other hand, MDF exhibits better resistance to moisture, making it a preferred choice for areas with higher humidity or potential exposure to water.

Applications and Best Uses: Chipboard vs MDF

Both chipboard and MDF find extensive applications across the construction and furniture industries.

Builders and designers commonly use chipboard for interior projects like shelving, cabinets, and furniture frames due to its cost-effectiveness and versatility.

For applications that demand a painted or veneered finish, MDF emerges as a preferred choice. Its superior surface smoothness and machinability make it ideal for crafting doors, mouldings, and decorative panels.

Melamine-faced MDF is commonly favoured for applications where a smooth, flawless surface and precise machining are crucial, such as high-quality furniture or decorative panels. Melamine-faced chipboard, on the other hand, may be preferred for cost-effective projects that prioritise durability and versatility.

Cost Considerations: Chipboard vs MDF

Affordability is a significant factor to consider in any project. Chipboard typically offers a more budget-friendly option compared to MDF, making it an attractive choice for those seeking cost-effective solutions.

However, it’s crucial to evaluate the long-term benefits and consider the specific project requirements when making a decision solely based on cost.

Chipboard vs MDF: Pros and Cons Comparison

Let’s summarise the key pros and cons of chipboard and MDF:

Chipboard:

Pros: Affordable, versatile, suitable for non-moisture-prone areas, easy to work with.

Cons: Prone to swelling and damage from moisture, less durable than MDF.

MDF:

Pros: Smooth surface, uniform density, better moisture resistance, excellent for painting or veneering.

Cons: Slightly more expensive than chipboard, heavy, requires proper sealing for moisture-prone applications.

Environmental Impact: Chipboard and MDF Sustainability

Considering the environmental impact is essential when making material choices. Both chipboard and MDF are made from recycled or sustainably sourced wood fibres, reducing their carbon footprint.

However, it’s important to look for certifications like FSC (Forest Stewardship Council) or E1 compliance for lower formaldehyde emissions, ensuring more environmentally friendly options.

Chipboard vs MDF: Which One Should You Choose?

In conclusion, selecting between chipboard and MDF depends on several factors, including the project requirements, durability needs, moisture exposure, and budget constraints. Assessing these aspects will guide you towards the ideal choice for your specific application.

By understanding the differences in material composition, structural properties, durability, moisture resistance, and cost considerations, you can confidently decide between chipboard and MDF. Remember to also consider the environmental impact of your choice and opt for sustainable options whenever possible.