How To Use Timber Connectors

| by Holly Wood

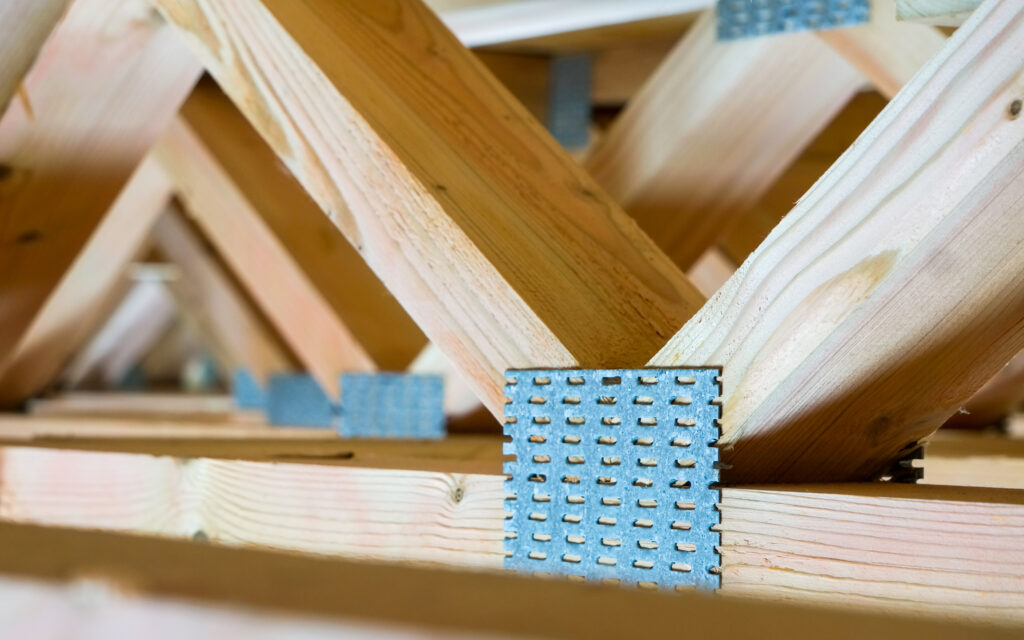

Knowing how to use timber connectors is a critical skill for those in the construction industry, especially when looking to build reliable and sturdy wooden structures.

These essential building accessories are pivotal in forming robust timber-to-timber and steel-to-timber joints.

To help you navigate the world of timber connectors, we’ve curated a comprehensive guide on using them effectively.

Understanding Your Timber Connectors

Before diving into the steps, let’s familiarise ourselves with the key types of timber connectors:

- Shear Plate Connectors: Contractors often use shear plate connections for timber to steel connections and timber to timber joints. These connectors improve bolt performance, thereby enhancing the load carrying capacity.

- Split Ring Connectors: Predominantly for timber to timber connections, these metal connectors fit into pre-cut grooves in the timber members.

- Tooth Plate Connectors: These connectors have teeth that dig into the timber, usually made from durable materials like galvanised steel. Toothed plate connectors with features on both sides are utilised for timber-to-timber connections subjected to lateral forces. On the other hand, one-sided toothed connectors are ideal for demountable timber joints and connections between laterally loaded steel and timber. The robustness of these connections hinges on the dimensions of both the timber and the connection, as well as the load-bearing capacity of the bolt.

Steps to Using Timber Connectors Effectively

- Select the Right Connector: Depending on your project’s requirements – be it timber to timber or steel to timber joints – choose the appropriate connector. Consider factors like timber density and the load carrying capacity you require.

- Prepare the Timber: If you’re using split ring connectors or shear plates, ensure you’ve produced pre-cut grooves in the timber. The grooves should be of the correct depth and size to fit the connector snugly.

- Drill Proper Holes: For connectors that require bolts, like shear plates and split rings, drill holes of the right diameter. The bolt diameter is critical to improving bolt performance.

- Position the Connector: Place the connector into its designated position. For instance, a split ring would fit into the pre-cut groove, while a tooth plate would need to be positioned so its teeth can grip onto the timber effectively.

- Secure with Bolts or Screws: Depending on the type of connector, secure it using appropriate wood screws or bolts. Ensure the screws or bolts are made of durable materials for extended durability.

- Use Washers: If the connector type demands it, use washers, especially square or large ones. Washers distribute the pressure and reduce bearing stresses on the timber.

- Check the Connection: Once connected, inspect the joint. It should be firm, without any wobbles. If necessary, tighten the screws or bolts further for a secure connection.

- Maintain Regularly: While timber connectors enhance the durability and strength of the joints, it’s essential to check them regularly, especially in structures exposed to external elements.

Common Mistakes to Avoid

- Mismatching Connector and Timber Dimensions: Always ensure the connector diameter matches the timber dimensions.

- Skimping on Bolts: For connectors like shear plates, ensure you use the required number of bolts for a firm hold.

- Improper Hole Sizes: Drilling holes too big or too small can compromise the connection’s strength. Always measure and drill accurately.

Conclusion

Understanding how to use timber connectors effectively can make all the difference in the longevity and reliability of your construction projects.

With this guide in hand, you can now maximise the benefits of these essential construction accessories.

Remember, precision is key – so take your time and ensure each connection is as robust as it should be!

Related Posts

Chipboard vs MDF: Unveiling the Differences and Making the Right Choice

40 Financial Experts Reveal If Investing In Real Estate Is Worth It

International Men’s Health Week: Our study into men’s health and a medical guide to treating common ailments

Insulation Rolls vs Insulation Slabs: Which Type is Better in a Partition Wall

Battle of the Builder’s Brew! Best way to make tea revealed (it’s never milk first, FYI)

Tidy house, tidy mind: Over half of Brits start DIY and home improvement projects to help mental health

Best in the bedroom: Survey reveals tradesmen make the best lovers

32% increase in ‘Doomsday Preppers’ building bunkers and safehouses